The PlasmaBox was created to improve the performance of a conventional PECVD (Plasma Enhanced Chemical Vapor Deposition) system. Here is a brief look at the PlasmaBox, its applications, and its benefits.

1. What is the PlasmaBox?

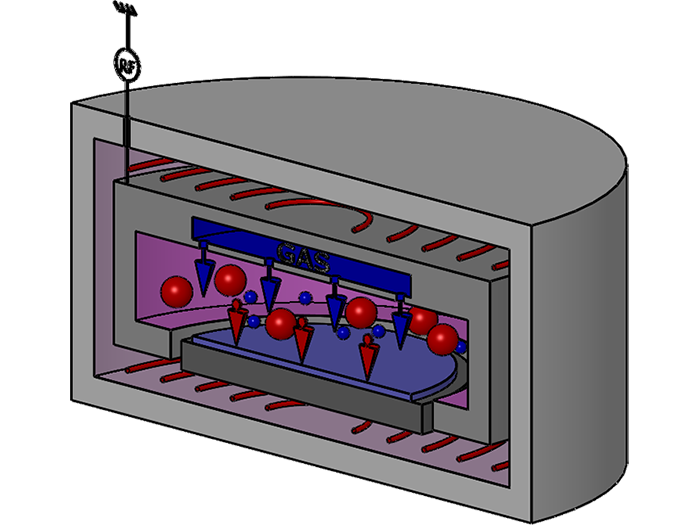

The PlasmaBox is a unique design; it is a box within a box. This hot wall reaction chamber is a variation on the design of a standard PECVD system. It differs in that the box inside a box concept allows for differential pumping. That means that there can be differential pressures between the inner box and the outer box. There is also the ability to have two different temperatures in a process - the inner box has hot walls, whereas the outer box remains relatively cool.

2. What is the motivation behind the PlasmaBox?

The motivation for the PlasmaBox was to address some of the equipment design principles of a typical PECVD. There is always room for improvement, especially in terms of better control of contamination.

In R&D, people are running many different films at varying conditions. Cold sidewalls can create as much deposition inside the chamber as is deposited on the wafer. With the standard PECVD, the process has to be stopped often for cleaning, increasing downtime. When the sidewalls are cold, and deposition is on a hot film, the film can crack under stress. Deposition materials create flaking, and the particles fly everywhere. There was also a need to minimize the chamber volume to help improve uniformity.

The small, confined hot wall of the PlasmaBox alleviates these issues.

3. What are some applications of the PlasmaBox?

The PlasmaBox has a wide range of applications.

- Capacitor filling

- Passivating the surface of a device

- Encapsulation to protect from the environment (water moisture, oxygen)

- Barrier layers to prevent diffusion

- Templates for growth techniques such as MBE and MOCVD

- Solar cells

- Anti-reflective coatings (sunglasses)

- Planarization to eliminate sharp topography

- Waveguides

PECVD films are used in many different capacities. Most devices have a wafer going through a process flow, and there can be numerous passes through the same tool. You don't just put down one film during fabrication but may end up putting down a dozen different films per device. It is all done with a variety of different kinds of films (SiO2, SiNx, SiON, SiOF, SiOCH, SiC) and those films are evaluated in many ways.

Important parameters for film include:

- Stress

- Uniformity

- Wet Etch Resistance

- Refractive Index Control

- Step Coverage

The PlasmaBox is integral to many devices.

4. What are some design features of the PlasmaBox?

The standard PECVD design is a parallel plate with a shower head used to disperse reagents uniformly. The powered electrode is much larger than the smaller electrode where the wafer sits.

The box within a box design of the PlasmaBox allows for equally sized electrodes. Pressure and temperature differential are also possible. You get a high-temperature inner box with temperature-friendly outer surfaces.

5. What are the benefits of the PlasmaBox?

High-Efficiency Cleaning

The hot walls of the PlasmaBox allow reactions to happen at a faster rate. You also get a more thorough cleaning. The MTBC (mean time between cleans) is more extensive, resulting in less downtime. Customers report the rarity of having to clean the chamber at all.

Stress Control

The electrodes in the PlasmaBox are equal in size. This helps control stress because an additional power supply is not needed. By adjusting the power you can adjust the stress. With PlasmaBox, extra power will make the film more compressive.

Low Contamination

The wafer inside the PlasmaBox only sees hot walls. These walls have no water vapor, so there is less hydrogen and less oxygen to contend with. Since the inner box has higher pressure than the cooler outer walls, contaminants go outward from high pressure to low pressure. This prevents contamination from coming inward and keeps things cleaner around the wafer.

Uniformity

A distributed pumping manifold inside the PlasmaBox provides good gas flow. It is pumping from everywhere, so gas is evenly distributed over the wafer. With gas flow in the laminar flow regime, the result is superior uniformity.

Low Wet Etch Rate

Films are used as hard masks for a wet etch process. In this case, you don't want the mask to be chemically reactive. With equal-sized electrodes, PlasmaBox allows for more ion bombardment. This generates a higher density film that is less reactive for wet etching.

PlasmaBox Summary

PlasmaBox is a high performance system applicable to a wide range of research and low volume production. It relies on the processes of PECVD with a hardware configuration to improve performance with many advantages.

To learn more about PECVD and its alternatives such as HDPCVD, download our free eBook “Comparing Chemical Vapor Deposition Systems: LPCVD vs. PECVD vs. HDPCVD.”