The only control software that broadens conventional tools’ process capabilities to enable time-multiplexed processes such as the Bosch Deep Reactive Ion Etch (DRIE) process, and Atomic Layer Etch or Deposition processing (ALE, ALD).

CORTEX® Pulse control software in brief

CORTEX® Pulse software is an add-on to the Advanced Process Control Software used with CORIAL systems.

CORTEX® Pulse can control and pulse (simultaneously and independently) all process parameters, including gas flow rate, working pressure, RF power, and ICP power.

CORTEX® Pulse software can be configured for new systems, and is available as an upgrade for CORIAL systems already installed at customer sites. It is compatible with both ICP-RIE and PECVD systems.

CORTEX® Pulse, combined with the appropriate electronic controller, delivers rapid process step switching, from 10ms up to 1 min for a single process step. This feature gives customers many options to precisely control etch processes.

CORTEX® Pulse is the ideal process control software for academics, and especially for researchers targeting advanced device manufacturing. CORIAL is the first company to offer enhanced functionality – from continuous to pulsed processing – in one tool, at a reasonable price.

Key benefits

Key benefits

R

SIMPLE-TO-USE GRAPHICAL USER INTERFACE

R

CONTROL OF DRIE-BOSCH, ALE, AND ALD PROCESSES ON CONVENTIONAL SYSTEMS

R

FLEXIBLE SOFTWARE FOR ADVANCED IC DEVELOPMENT

Key features

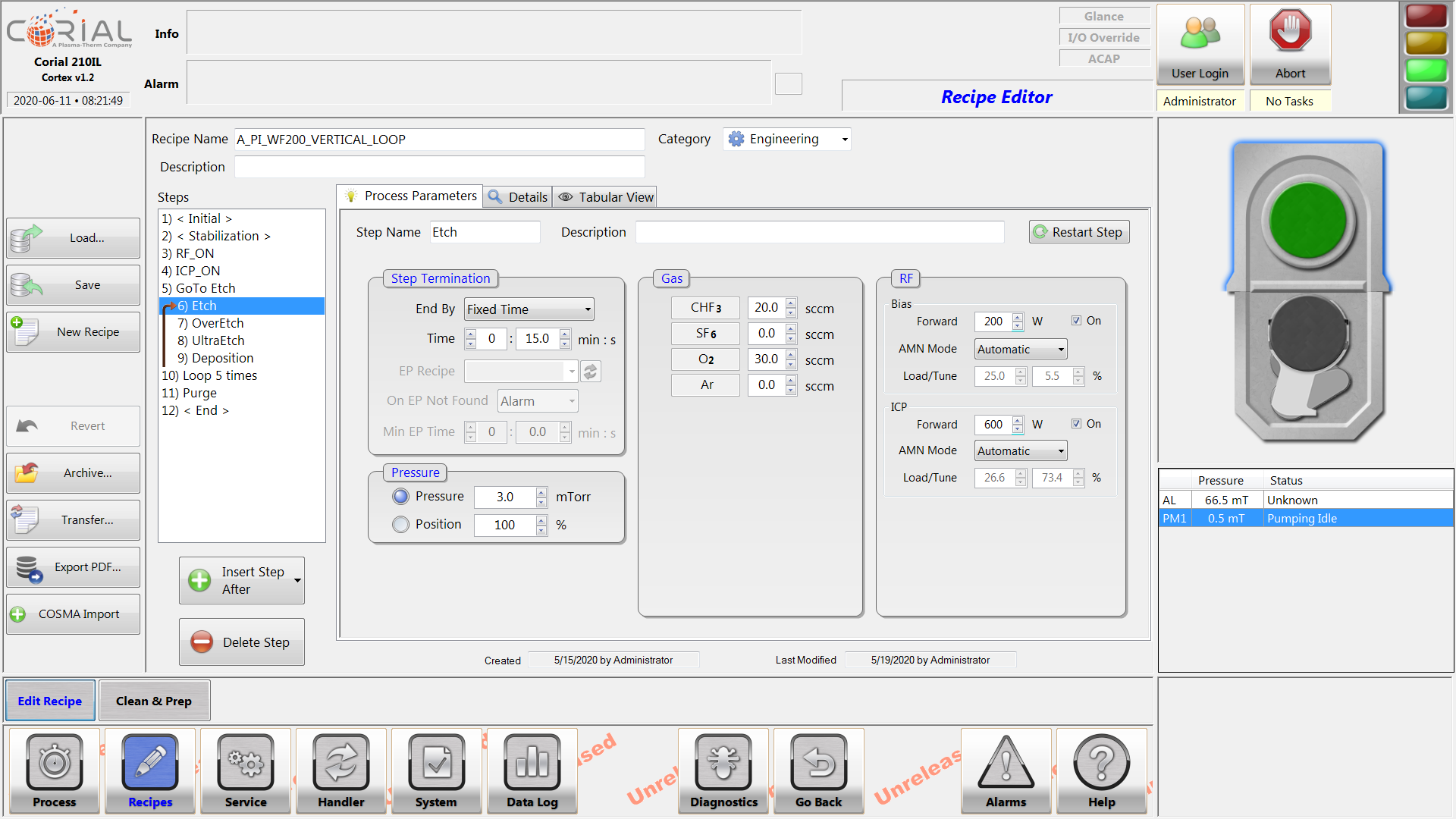

Process editing

Quickly create, optimize, and customize new process recipes with time-multiplexing.

CORTEX® Pulse features intelligent process control, using not only the standard “SET to” and "RAMP to” functions, but also an added “PULSE” function.

CORTEX® Pulse controls and pulses any process parameter (such as gas flow rate, RF and ICP power, working pressure, etc.), with a minimum pulsing period of 10 milliseconds.

Edit, store, use, and duplicate process recipes with the CORTEX® Pulse unique user interface.

Process adjustment

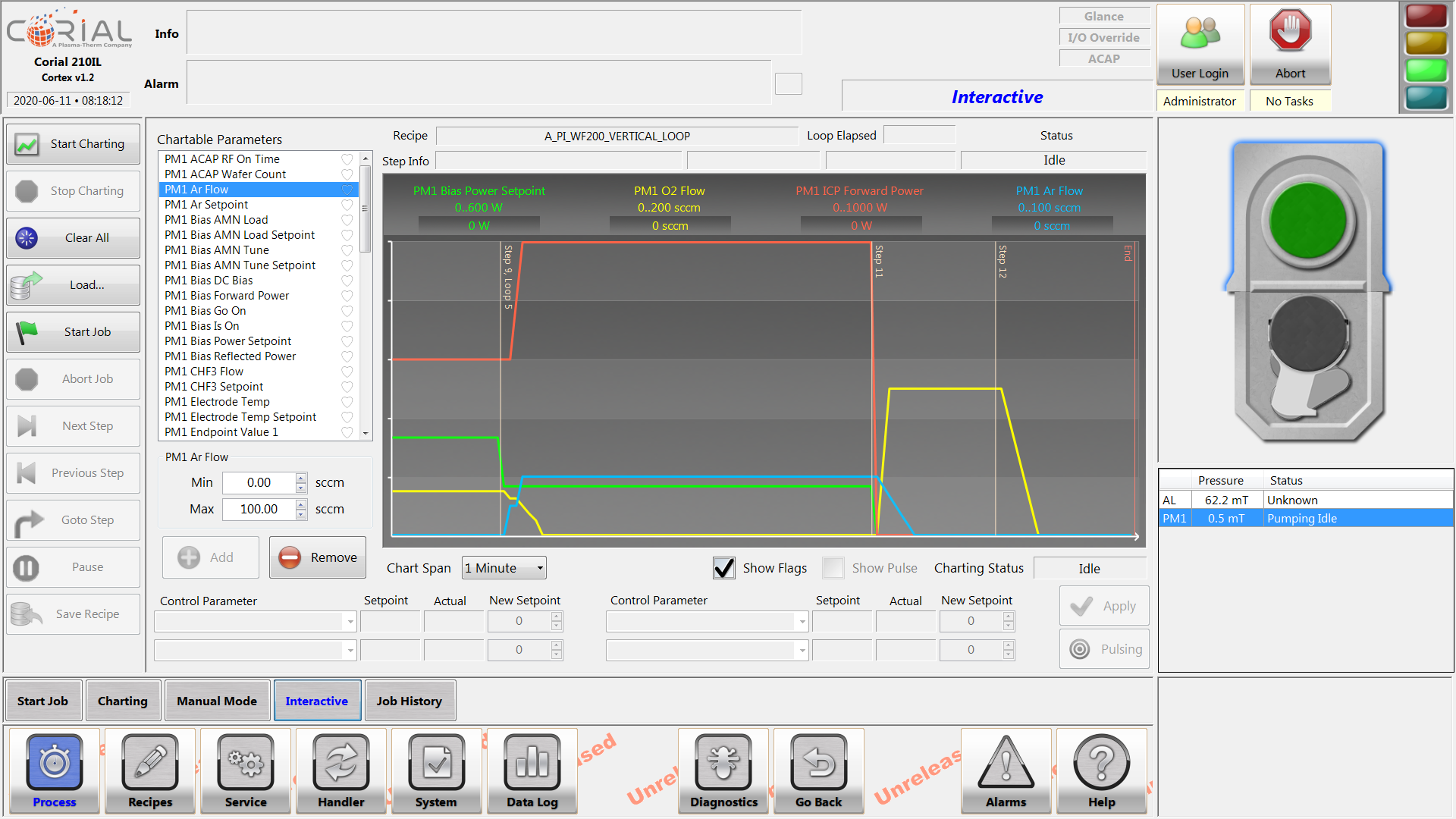

Use CORIAL’s exclusive interactive process control and editing to quickly optimize and fine tune your time-multiplexed recipes.

Perform diverse actions while running processes, such as pulsing any process parameter, toggling ICP power (On / Off), or transitioning to a different step.

Control of atomic scale etching

A promising technology

As CDs approach the sub-10 nanometer scale, conventional continuous etch-processes no longer provide the level of control required.

To continue technology scaling in logic circuits and memory devices, chip makers and academics now require atomic-level precision manufacturing to ensure control of feature dimension, ultra-high etch selectivity, and low damage.

CORTEX® Pulse features for atomic-scale precision etching

- Plasma enhanced ALE for high precision etching

- Reduced byproduct deposition on reactor walls to enable faster switching of process conditions and better reproducibility

- Advanced tuning of RF pulsing to control ion energy

- Independent and rapid pulsing of chlorine and argon flows during adsorption and desorption steps

- Real-time process adjustment

CORTEX® Pulse performances

CORTEX® Pulse software enables the etching of semiconductor and dielectric materials with atomic-scale precision.

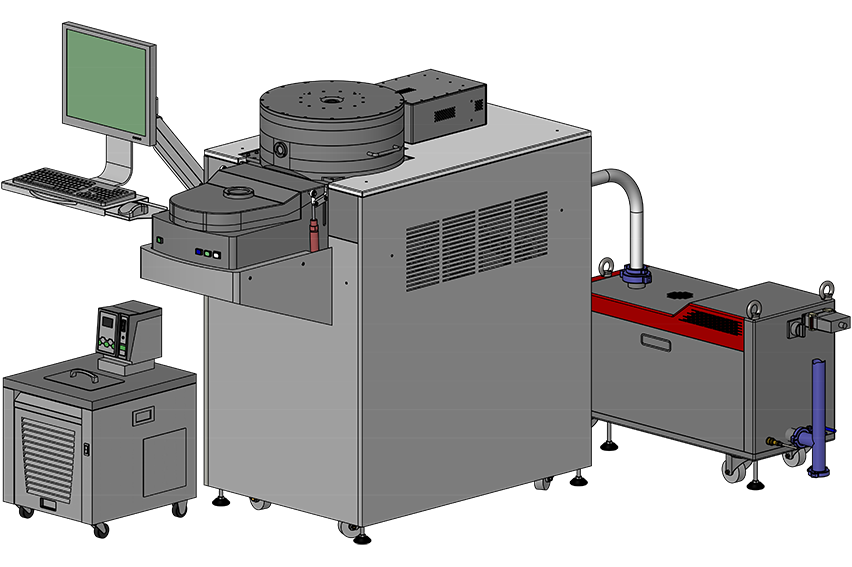

Silicon etch rate of 1.67 nm/min with atomically smooth surfaces can be achieved on CORIAL’s conventional 200 mm ICP-RIE system, the Corial 210IL.

Control of DRIE Bosch

The industry-standard technology for MEMS manufacturing and packaging

Deep Reactive Ion Etching (DRIE) of silicon, achieved via the Bosch or cryogenic microfabrication technologies, is routinely used for MEMS manufacturing to create deep micro-structures with high aspect ratios.

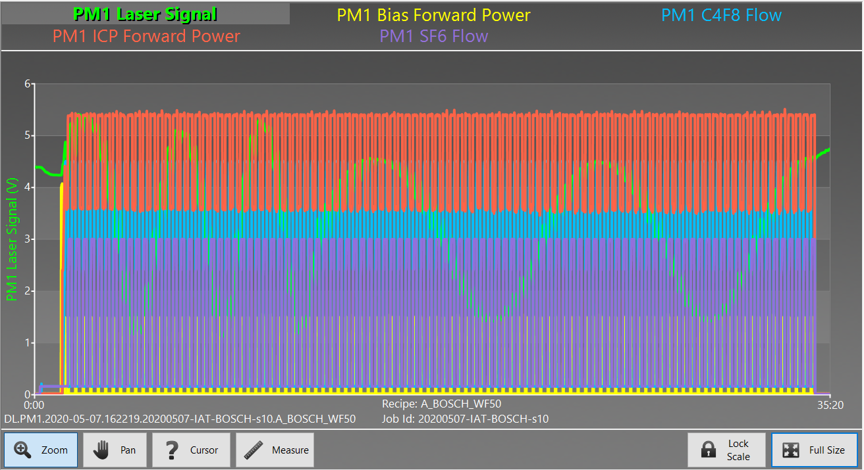

The DRIE-Bosch process enables deep anisotropic etching of silicon by employing a cyclic repetition of etching and passivation steps.

CORTEX® Pulse features for DRIE-Bosch applications

- Rapid pulsing of RF power and gas flow rates

- In-situ end point detection with laser interferometry

- Real-time process adjustment

CORTEX® Pulse performance

Silicon through-wafer etch with selectivity vs. mask > 180:1.

Silicon etch rate > 3 µm/min with smooth sidewalls can be achieved on CORIAL’s conventional 200 mm ICP-RIE system, the Corial 210IL.

Process operation

Multiple user access rights

Password controlled login with different levels of user access.

Multistep management

Automatic transition to the next process step, based on signals from endpoint detectors or process timers.

Real-time process data display

All process parameters can be monitored simultaneously in real time during process execution.

Process reproducibility

Each process step is tightly controlled and monitored, to ensure reproducibility and optimum performance.

System compatibility

Atomic Scale Etching on Corial 210IL

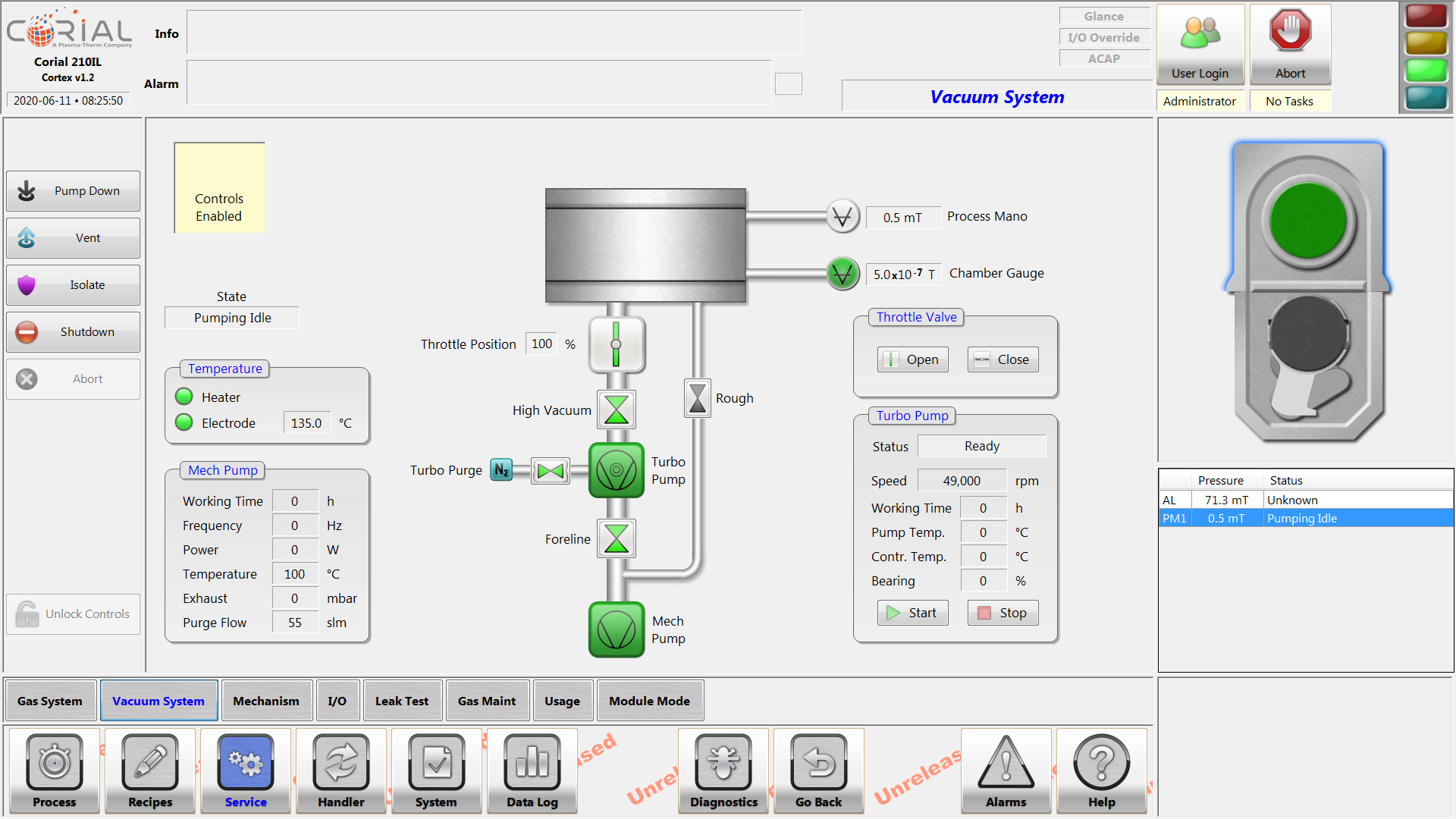

CORTEX® Pulse can be easily installed on Corial 210IL 200 mm etch systems to enable ALE capability for our conventional ICP-RIE systems.

Atomic Scale Deposition on Corial D250

CORTEX® Pulse can be easily installed on Corial D250 200 mm plasma enhanced deposition systemsto add ALD capability to our conventional PECVD systems.

DRIE-Bosch on Corial 210IL

CORTEX® Pulse can be easily installed on Corial 210IL 200 mm etch systems, enabling DRIE capability on our conventional ICP-RIE systems.

Upgrades

CORTEX® Pulse upgrade are available for all installed CORIAL systems.