Technology for film deposition on temperature and damage-sensitive substrates

Inductively Coupled Plasma – Chemical Vapor Deposition (ICP-CVD) is the method of choice for deposition of Si-based materials at low substrate temperatures, typically below 150°C.

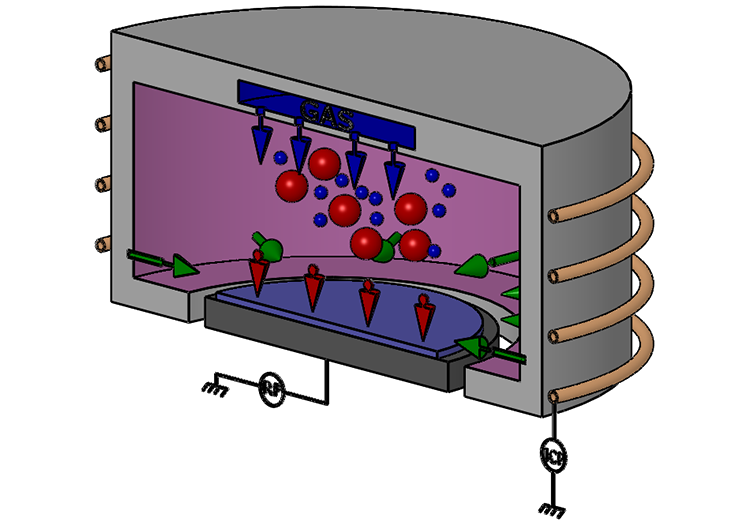

ICP-CVD technology

ICP CVD uses a high-density inductively coupled plasma source which operates in the low pressure range (from milliTorr to tens of milliTorr).

RF substrate biasing enables tuning of mechanical properties of deposited thin films.

In situ doping of the deposited films can be achieved via addition of a suitable dopant to the reactant gases.

ICP-CVD equipment

ICP CVD equipment features a unique design of two showerhead gas inlets to generate and efficiently transport reactive species to the substrate.

- Precursors such as silane, and dopant gases are injected into the plasma, just above the substrate.

- Inert gases are injected into the chamber through the upper showerhead, so that other highly reactive species, e.g., oxygen and nitrogen are generated in the bulk plasma.

For added flexibility, an ICP-CVD reactor can be easily and cost-effectively converted to an ICP-RIE etch reactor.

ICP-CVD processes

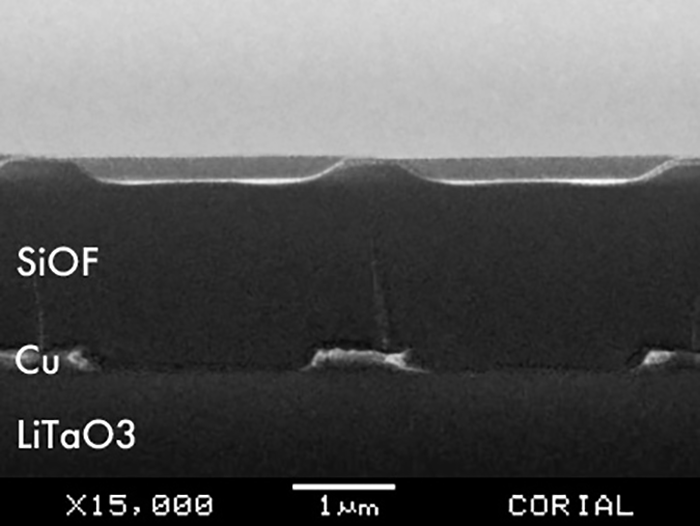

Using ICP CVD, it is possible to achieve film densities similar to PECVD, with good step coverage and at lower process temperatures. Also, the low ion energies with ICP CVD reduce damage to sensitive devices.

ICP CVD can be used to deposit a wide range of materials, including silicon oxide, silicon dioxide, silicon nitride,diamond like carbon, and amorphous silicon.

Products

Products

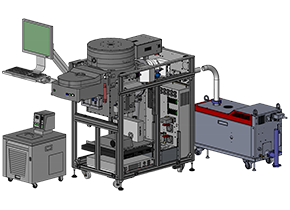

Corial 200 Series ICP-CVD System

Corial 210D

- ICP-CVD system for R&D

- Low temperature deposition

- High quality SiO2, Si3N4, SiOCH, SiOF, SiC and aSi-H films