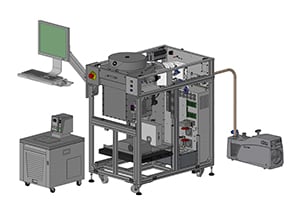

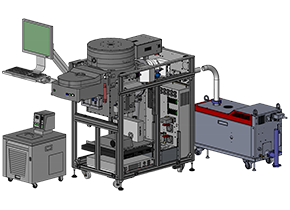

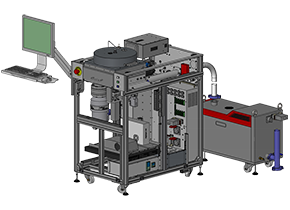

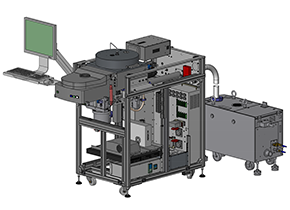

Shuttleline® 200 – Etch tools and deposition tools For R&D and Low Volume Production

Etch and deposition tools for wafer processing up to 200 mm with single substrate loading

The Shuttleline 200 is a flexible and scalable platform for etch and deposition applications. The platform can accommodate a whole host of substrate sizes and handling configurations, plasma processing technologies, and process chemistry configurations.

This platform is ideally suited for R&D and low volume production, handling up to 200 mm wafer sizes.

The process recipes developed for the Shuttleline 200 provide etch and deposition solutions for a broad range of markets, including failure analysis, microelectromechanical systems (MEMS), optoelectronics, advanced packaging, wireless devices, and power semiconductors.

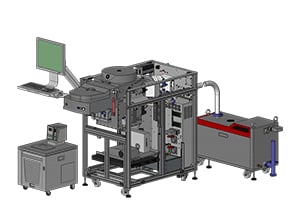

Shuttleline 200 RIE Etch Systems

Shuttleline 200FA

This RIE etch system combines the advantages of high etch rates with low cost of ownership for IC failure analysis applications. The Shuttleline 200FA is installed in major fabs worldwide, and features simple, direct loading of packaged dies, and dies up to 10x10 mm.

Shuttleline 200S

This simple-to-use, manually-loaded RIE system can etch a wide range of materials including silicon, silicon-based compounds, metals, and polymers with fluorinated gases. Shuttleline 200S is well suited for R&D and can process from small wafer pieces to a full 200 mm wafer.

Shuttleline 200R

Compact RIE system for etching silicon-based compounds, metals, and polymers. With a direct-load design suitable for wafer pieces, or up to full 200 mm wafers, the Shuttleline 200R is the ideal equipment for R&D and prototyping.

Shuttleline 210RL

Designed with a vacuum load-lock, the Shuttleline 210RL provides RIE etching capabilities over a variety of materials including silicon, silicon compounds, polymers, III-V & II-Vi compounds semiconductors and metals.

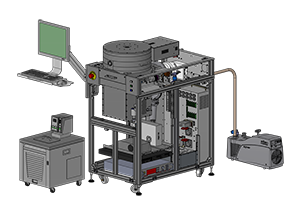

Shuttleline 200 Series ICP-RIE Etch Systems

Shuttleline 200I

The Shuttleline 200I ICP-RIE system was designed with R&D centers and IC failure analysis labs in mind. The equipment uses fluorinated and oxygen-based chemistries to provide excellent etch rates and uniformities across multiple substrate types (dies, packaged dies, and wafers up to 200 mm).

Shuttleline 210IL

This etcher is based on CORIAL’s latest generation of ICP reactor. The 210IL system includes a vacuum load lock, and features high density plasma, helical antenna, 2 MHz ICP RF generator and quartz liner, enabling high etch rates and excellent uniformities.

Shuttleline 200 Series ICP-CVD Systems

Shuttleline 210D

The Shuttleline 210D ICP-CVD system is ideal for the R&D environment, and offers a wide range of applications that serve the specialty semiconductor markets. The system operates in ICP mode to deposit high quality SiO2, Si3N4, SiOCH, SiOF, SiC, and aSi-H films at low temperatures.

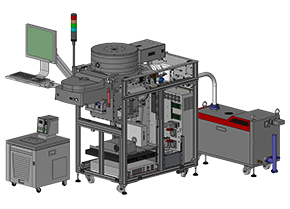

Shuttleline 200 Series PECVD Deposition Systems

Shuttleline D250

The Shuttleline D250 PECVD system is designed for R&D and low volume production. This deposition tool is based on Shuttleline PECVD reactor. It accommodates wafers of up to 200 mm in diameter, and offers rapid deposition rates for SiO2, Si3N4, SiOCH, SiOF, SiC and aSi-H films.

Shuttleline D250L

The Shuttleline D250L is ideal for R&D and low volume production. It serves a broad range of applications in the specialty semiconductor market. Featuring a vacuum load lock, the Shuttleline D250L ensures stable process conditions, short pumping cycles, and enhanced throughput.