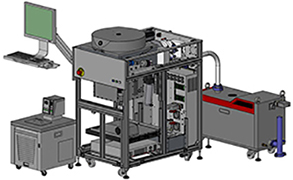

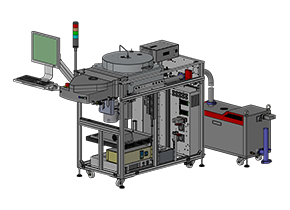

Shuttline® 300 SERIES – Etch tools and deposition tools for 24/7 Production Environment

High throughput etch and deposition tools with batch loading for wafer processing up to 300 mm

Designed for the 24/7 production environment, the Shuttleline 300 offers high-capacity batch loading to drive down production costs without compromising process performance.

All Shuttleline 300 systems are built with highly reliable components to achieve high system uptime.

The Shuttleline 300 systems are ideal for volume production film etch and deposition for the optoelectronics, MEMS, photomask, and power semiconductor markets.

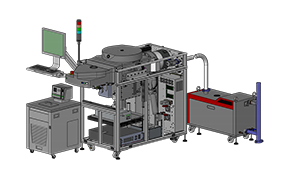

Shuttleline 300 RIE Etch Systems

Shuttleline 300S

With chrome and quartz etch capabilities, the Shuttleline300S RIE system is ideal for mask repair. This product can process mask sizes from 2” x 2” up to 8” x 8”, thanks to a wide array of substrate holders.

Shuttleline 360RL

The Shuttleline 360RL RIE system is ideally suited for etching III-V compounds such as GaAs, GaP, GaN, and AlGaN. This RIE etcher is also capable of etching chrome and quartz for mask repair applications.

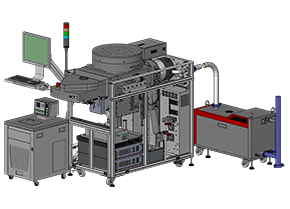

Shuttleline 300 ICP-RIE Etch Systems

Shuttleline 360IL

The Shuttleline 360IL is a large area plasma etch system offering high throughput, without compromising process performance or quality. Our PSS (patterned sapphire substrate) processes deliver perfect conical-shaped features, even at the wafer edge, with industry leading uniformity and repeatability.

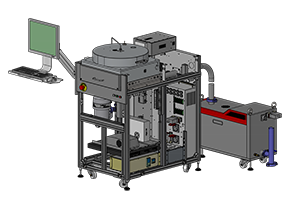

Shuttleline 300 PECVD Deposition Systems

Shuttleline D350

The Shuttleline D350 PECVD system is designed to produce high-quality, uniform films for photonics, optoelectronics, and MEMS device manufacturing. This PECVD system can operate for years without the need for manual cleaning.

Shuttleline D350L

The Shuttleline D350L PECVD system offers fast and uniform deposition on full 300 mm wafers, or large batch capacity. Equipped with a vacuum load lock, the Shuttleline D350L delivers stable process conditions, and short pump-down times.