Production-proven dry etch processes and equipment dedicated to the photomask industry

Photomask market overview

The photomask is an essential component in the microlithography process used for the manufacture of integrated circuits, photonic devices, and micro-electro-mechanical systems. It is a transparent plate generally made of quartz or glass, coated with an opaque film with holes or transparencies that permit light to pass through in a defined pattern.

A functioning device can require between up to 40 individual photomasks, one for each step used in the fabrication process.

CORIAL solutions

Leveraging our experience in the fields of metals and hard materials processing, CORIAL has been a supplier of cost-effective dry etch systems to the photomask market since 2004.

CORIAL provides innovative plasma process solutions for the full range of photomask formats, materials, and technologies, including chrome etching for binary masks, and quartz etching for alternating aperture phase-shift masks (AAPSM).

CORIAL Advantages

CORIAL Advantages

R

Process solutions for binary masks and AAPSM

R

Lowest cost of ownership equipment

R

Highly uniform, clean and selective etching

Etch processes

Etch processes

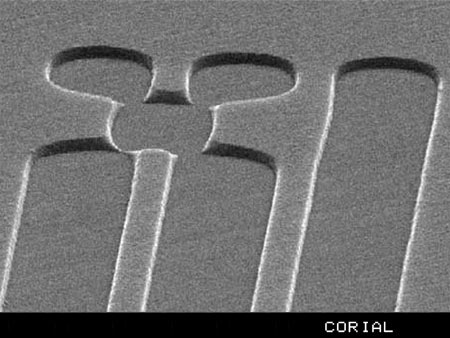

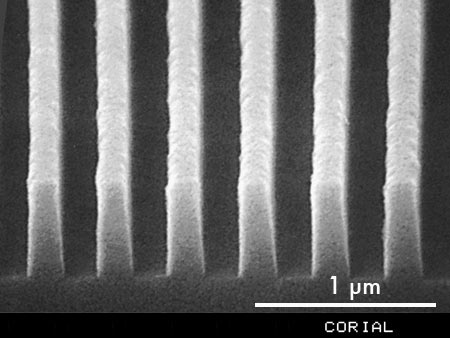

CORIAL plasma process solutions are key enablers for chrome etching and quartz etching.

Our products can etch films for a wide variety of technology nodes with vertical profile, CD loss ≤±0.1 µm, etch line width < 0.5 µm and mask to mask uniformity ≤±3%.

Products

Products

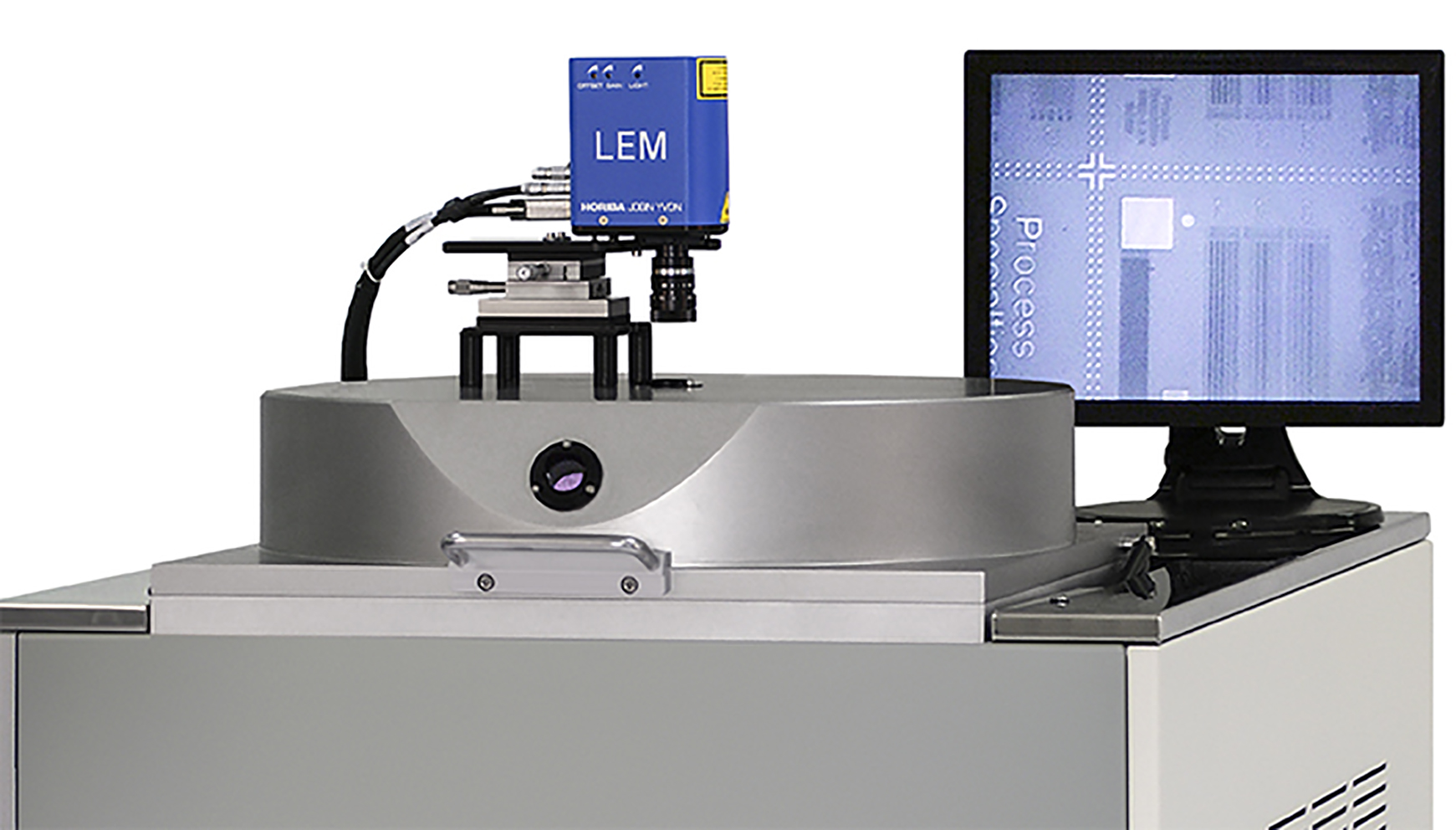

Corial 300S

- Processing of masks up to 8”x8”

- High process stability with mask to mask uniformity < ± 3%

- Low cost of ownership

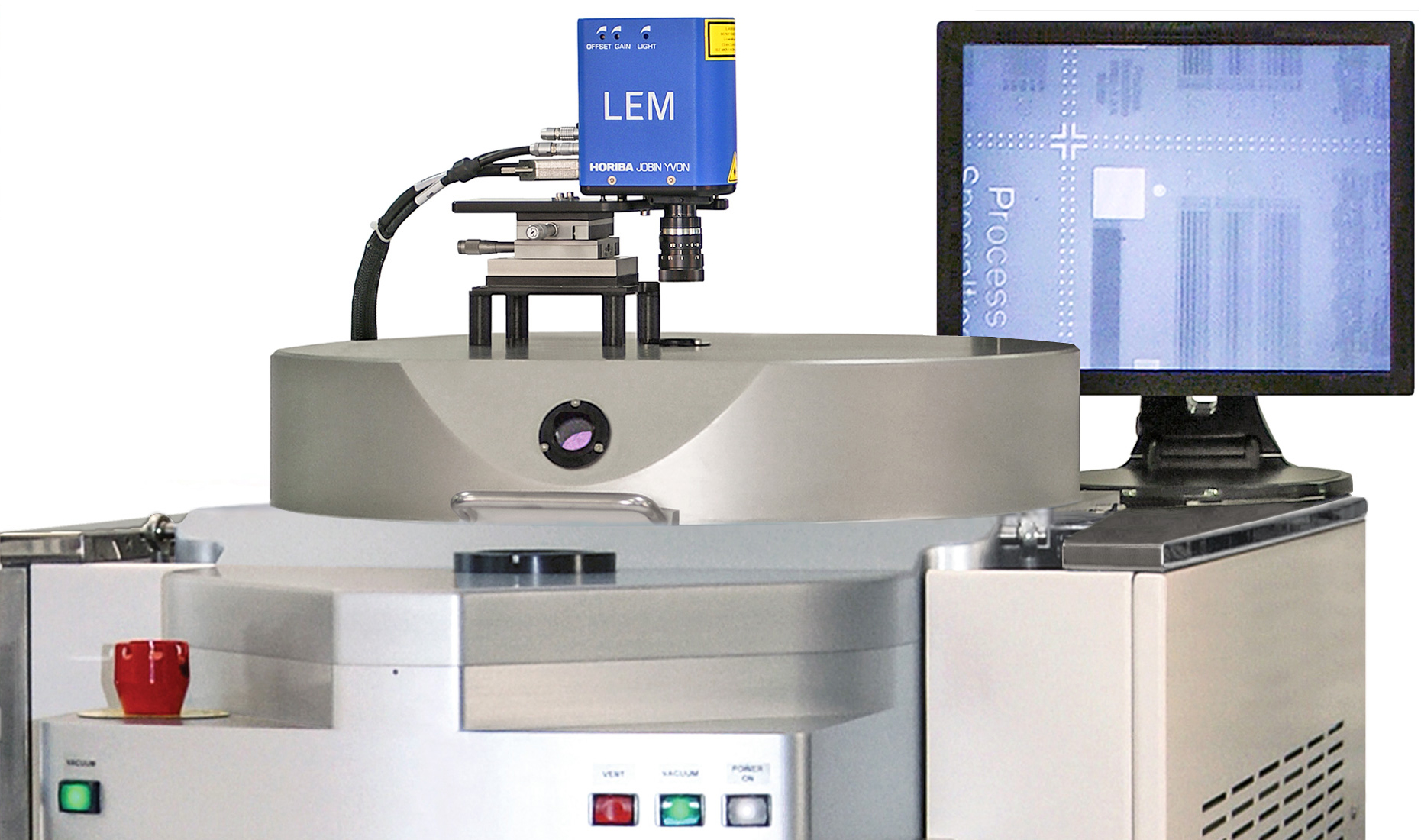

Corial 360RL

- Processing of masks up to 8”x8”

- Highly uniform and selective etching

- High system uptime