Plasma enhanced deposition

Creating a vast array of thin films with PECVD and ICP CVD technologies

Fourth state of matter

Plasma is one of the four states of matter, along with solids, liquids, and gases. Plasma is an ionized gas consisting of equal numbers of positively-charged ions and negatively-charged free electrons. Thus, in plasma overall electrical neutrality is maintained.

Plasma is a common part of the world we live in. Along with nebula, interstellar space, and solar wind to mention a few, about 99% of the universe is made of naturally-occurring plasmas.

Plasmas are broadly used in technologies we interact with on a daily basis. Consider fluorescent lamps and neon signs – they are made of glass tubes filled with gas. When the lamp is turned on, the gas becomes ionized, electric current starts flowing through the tube, electric energy is dissipated, generating ions, electrons and excited molecules. This molecular excitation-relaxation process creates the characteristic plasma glow discharge inside the tube that illuminates the surrounding environment.

Plasma generation

The practical means to create plasma is to apply an electric field to a low-pressure gas.

Any free electron (created by a cosmic electron, for example) can be accelerated and gain enough energy to ionize a molecule by collision.

So, an electron/positive ion pair is created. The new free electron will continue the process and the plasma will be established by this chain reaction.

Application of plasma enhanced deposition in the semiconductor industry

Along with Physical Vapor Deposition (PVD), Chemical Vapor Deposition (CVD) is one of the technologies used to create diverse thin films and coatings such as metals, oxides, or silicon.

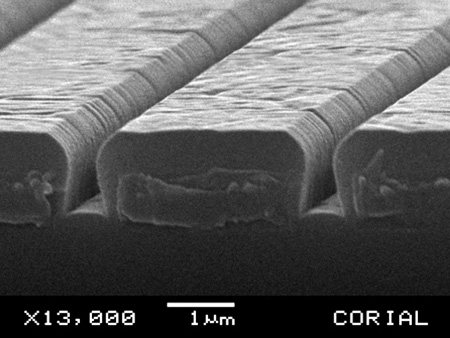

Plasma Enhanced Chemical Vapor Deposition (PECVD) is a variant of CVD that uses plasma to enhance the properties of deposited layers.

Plasma enhanced CVD has been extensively used in the semiconductor industry to fabricate integrated circuits, photovoltaic, photonic, optical, and biomedical devices.

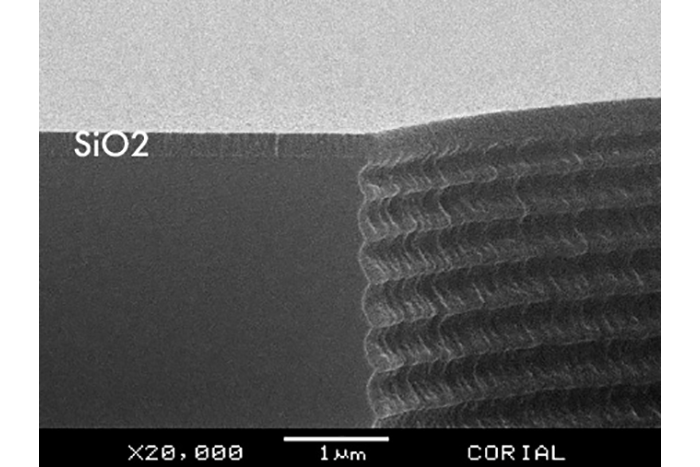

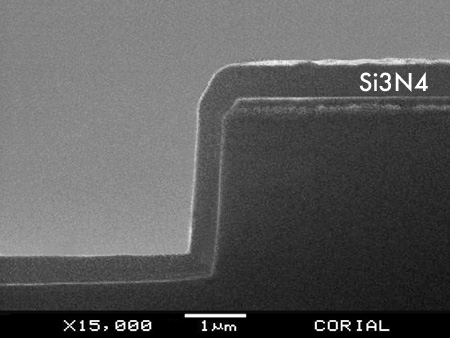

Besides conventional materials used in microelectronics, such as dielectrics (SiO2, Si3N4), low-k dielectrics (SiOF, SiC, etc.) and silicon layers, many other materials can be deposited with PECVD. These materials include metal oxides and nitrides, and carbon-based materials. Depending on which deposition precursors are used, the films can be doped in situ (during PECVD process).

Plasma enhanced deposition principles

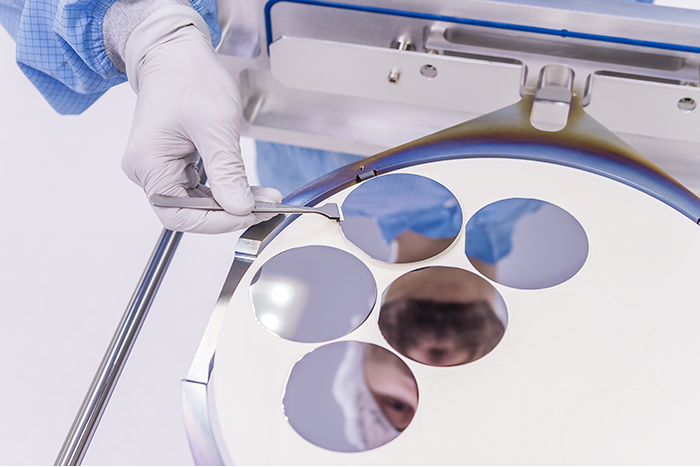

Plasma Enhanced Deposition technology makes it possible to deposit layers of different materials, over substrates of various shapes and sizes, with highly uniform film properties and thicknesses.

Chemical adsorption

The PECVD mechanism begins with the activation of precursor molecules in a plasma when they collide with highly energetic electrons. These reactive species are transported to the substrate surface via gas flow and diffusion through a gas boundary layer.

Byproduct formation

Upon adsorption, the active species migrate along the substrate surface, seeking active sites, where chemical reactions occur to effect film deposition, and deposition byproducts are formed.

Desorption

The reaction byproducts then desorb from the deposition surface, are pumped away from the deposition reactor, and the deposition of film with the desired composition is complete.

Plasma enhancement of a CVD process is typically performed at low pressures, in the range of several milliTorr up to tens of Torr.

Typical deposition temperatures range from 50°C to 400°C.

Depending on the desired film properties and allowable process conditions, PECVD reactors employ both capacitively coupled and inductively coupled plasmas. In both cases, an electric field forms and causes electrons to accelerate, which creates ions and other reactive species. Energy of ions striking the substrate surface, along with the reactive gas composition both participate in the film’s mechanical stress properties.

Advantages of plasma enhanced deposition

Low temperature processing

Tight control of film composition and uniformity

Adjustable film properties, such as stress and refractive index

Deposition technologies

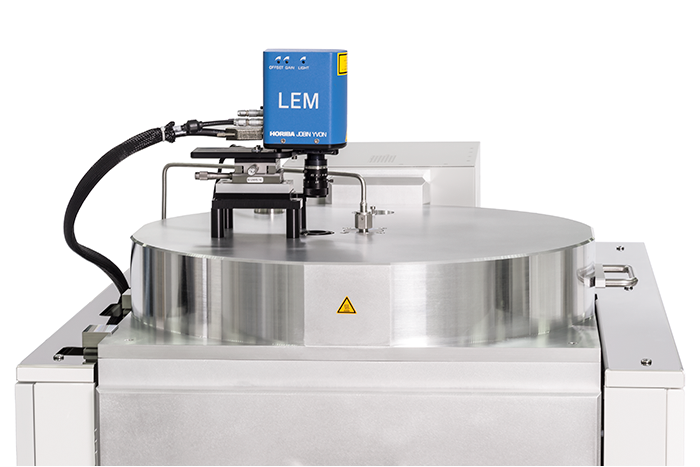

Plasma Enhanced Chemical Vapor Deposition (PECVD)

PECVD is a versatile method used to deposit many different types of materials, including Si, SiO2, Si3N4, a:Si-H, etc., at a low pressure in the range of hundreds of milliTorr up to hundreds of Torr.

Inductively Coupled Plasma – Chemical Vapor Deposition (ICP -CVD)

ICP-CVD is a method of choice for deposition of Si-based materials at low substrate temperatures typically below 150°C.