For VCSEL and laser diode bars used in medical applications, CORIAL 200 Series ICP-etch system delivers high uniformity and best-in-class etching reproducibility.

An equipment optimized for VCSEL and laser diodes

CORIAL 210IL ICP etcher enables volume production of VCSEL and laser diode bars on up to 4” wafers. Key etch requirements include uniformity of etch depth and excellent process reproducibility, which is needed for manufacturing environments.

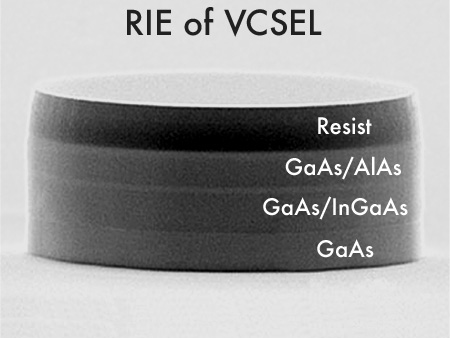

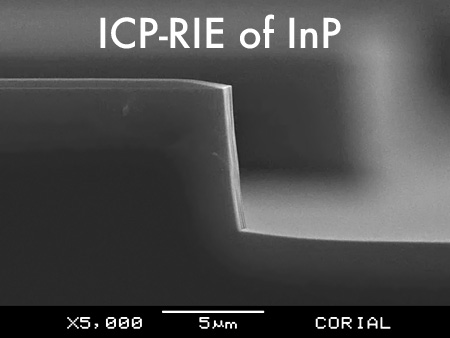

The Corial 210IL is built upon a production-proven ICP plasma source technology featuring hot walls and RF match box with matching range of 100 to 2000 W. Such flexibility enables to accommodate the wide range of applications notably in medical laser systems, including etching of AlхGa1-хAs/GaAs/InGaAs layers, etching AlInAs/GaInAs/InP layers and etching of InGaP/GaAs.

Leveraging new cathode design and efficient helium back side cooling of the shuttle and substrate, the ICP system also keeps uniform temperature control (from -50°C) during the etch process to provide the best run-to-run repeatability.

An agreement signed with a leading manufacturer of medical devices

As a result, CORIAL has just won a major deal with a leading manufacturer of laser medical devices in CIS (Conductor Insulator Semiconductor). The company based in Russia has strong production capabilities and focuses on manufacturing of systems used across such applications as cosmetology and healthcare.

In this particular case, our customer specified GaAs and InP substrate thicknesses that are not traditionally used.

Our unique shuttle design, combined with a standard cathode, allows a cost effective reactor adaptation in order to fit with various substrate forms and sizes. We designed in less than a day customized shuttles to suit the required wafer thickness while minimizing edge exclusion.

Process performances for medical laser systems

Corial 210IL in an ICP-RIE system with vacuum load-lock for up to 200 mm substrates. It uses chlorinated reactive gases for III-V materials like GaN, AlGaN, GaAs, or InP etching.

- Etch rate 1200 nm/min

- Uniformity ±3%

- Selectivity vs. SiO2 mask > 50