Plasma processing chambers are among the heaviest used types of systems in the manufacture of wafer-level electronics. Whether it be for discrete device research or more complex integrated circuits, plasma processing plays a critical role. For this reason, it is important to understand how to keep it at optimum operating performance.

The constraints on funding and cleanroom space are well known and the result is a desire to maximize the utilization of any system. Part of that optimization means reducing unscheduled downtime events as much as possible. Improving unscheduled downtime usually involves scheduled maintenance activities. The goal is to keep the process chamber up and running in its most productive state. This involves three primary activities:

- Maintenance

- Calibrations

- Cleaning

Attention to these activities will help ensure you are getting the best performance from a plasma etching system.

Maintenance: Vendors provide a recommended schedule for inspections which includes periodic replacement of some parts. These parts are often referred to as consumables and include items such as O-rings and belts. During these planned activities, the entire system is examined for signs of wear and replaced or cleaned as needed. This includes the wafer clamp, rf cables, moving parts (such as the robot or any motor or spring driven component), sensors (such as toxic gas, fire, or gas box interlocks), and safety switches (such as the emergency power off button).

Calibrations: Component performance can drift, making it essential to check those components responding to recipe requests frequently. Periodic checking to see components are both precise and accurate is useful when the goal is reproducible results. Components such as mass flow controllers (MFCs), pressure gauges, rf power, bias values and component temperatures (e.g. electrode or heat exchanger) should all be periodically calibrated. The more critical the process, the more frequently it should be done.

Cleaning: After getting specific results, getting reproducible results is perhaps the most important behavior of a system. Process chambers change with usage and some of that change can be attributed to components that drift. However, some drift is not due to components but rather to the chamber itself changing.

One of the most frequent questions regarding processing is, “How often should the chamber be cleaned, and what does it involve?” The answer to both parts depends on how the chamber is used. It is difficult to predict the frequency of cleanings without knowing what is being etched, what chemistry is being used, and the mask.

Chambers that are used in production are typically dedicated to a particular process. Processes that utilize chemistry that is known to produce polymers such as fluorocarbons or methane usually require cleaning more frequently than other processes. But that is not always the case.

For example, using etching conditions with relatively high bias where there is significant sputtering of the mask may also induce more frequent cleaning. Examples of this include etching of “hard” materials such as silicon carbide, quartz, or aluminum oxide. In these cases, and others, the mask material often redeposits on chamber surfaces. Over a period of time, the redeposition can impact the inductive coupling of the rf which affects the etch rate.

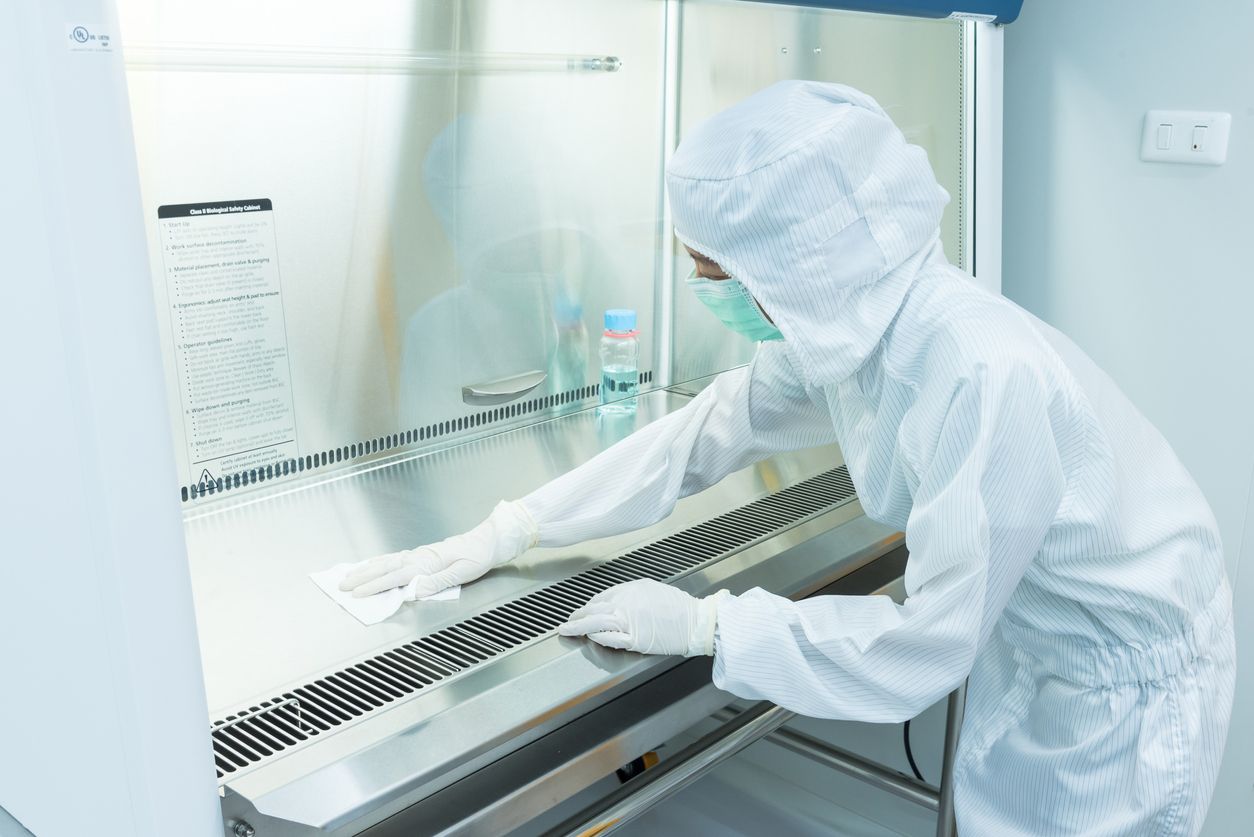

Cleaning is usually measured in rf-hours to normalize the amount of etching, but it can also be monitored by the amount etched or by the number of wafers. Keep in mind that there are two types of cleaning: Dry cleaning with plasma and wet cleaning where the chamber is opened. Dry cleaning can be done by setting a routine. Sometimes it can be as simple as running an oxygen plasma for 20 to 30 min every 10 hours of rf processing time.

At some point, the chamber will likely need to be opened for a more thorough cleaning. The usual wet clean consists of acetone, water, isopropanol wipe downs. In some cases, it is more expedient to do a quick replacement (changeout or swap) of a few parts and clean the old parts offline. The interval for a wet clean is typically much larger than for dry cleans and may be 100s of rf hours. However, there are situations where even the wet clean is fairly frequent.

It is more difficult to predict cleaning frequencies in an R&D environment with a much larger set of variables (different gas chemistries, materials, masks, and expected results). Systems with optical emission spectroscopy capability can monitor chamber cleanliness.

Whether the system is in a production or research environment, establishing baselines for tool functionality and processes performance is important. Upon installation of a new, clean system one of the first pieces of data to collect is the pump-down curve and leak-up rates. This data will prove invaluable later in a system’s life. The next piece of data is to record the etch performance and log the system values using a fixed recipe and material. Knowing the original performance for etch rate and uniformity while simultaneously knowing the system’s details such as matching network positions, throttle valve position will immeasurably help monitor the system’s performance and troubleshooting if ever needed.

Have questions about cleaning plasma chambers? CORIAL is here to help, just leave us a message.