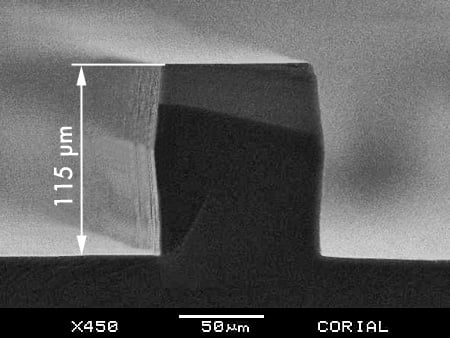

High etch rate, superior profile control, smooth surface, excellent selectivity for etch depths greater than 100 µm

Deep etching of silicon, achieved using the Bosch process or cryogenic microfabrication technologies, is routinely used for MEMS manufacturing to create deep micro-structures with high aspect ratios.

Besides silicon, a number of hard-to-etch materials typically glass, quartz, silicon carbide, and lithium tantalate, appeal to designers in the MEMS and packaging industries, because of their unique properties, and/or to decrease manufacturing cost. One of the main challenges in adopting these hard-to-etch materials is the formation of deep structures using Deep Reactive Ion Etching (DRIE) technology.

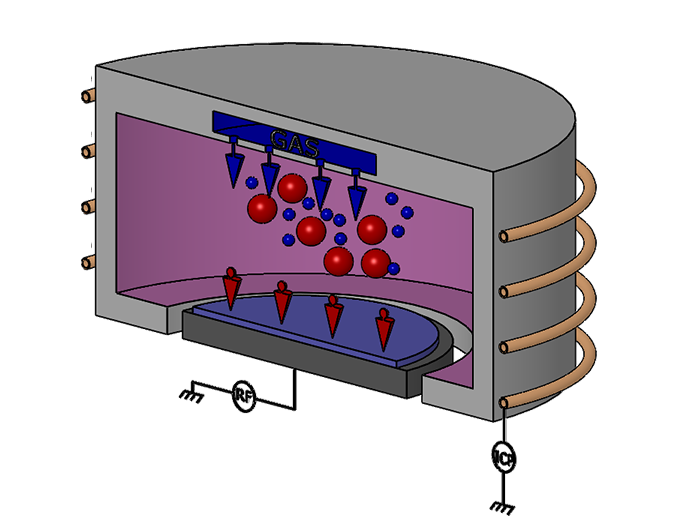

DRIE technology

Deep Reactive Ion Etching is enabled by equipment that can achieve high density of reactive species, and independent control of ion current and ion energy.

The ICP source generates a high-density plasma due to inductive coupling between the RF antenna and plasma. The antenna, located in the plasma generation region, creates an alternating RF magnetic field and induces RF electric fields, which energize electrons that participate in the ionization of gas molecules and atoms at low pressure. Due to the absence of an electric field near the reactor walls, there is virtually no ion bombardment or erosion of the walls.

A separate RF power source is connected to the cathode in order to generate DC bias and attract ions to the wafer. Thus, it becomes possible to decouple ion current and ion energy applied to the wafer.

The key differentiation between DRIE and conventional ICP-RIE, is that DRIE enables faster etch rates and the formation of deep etch structures.

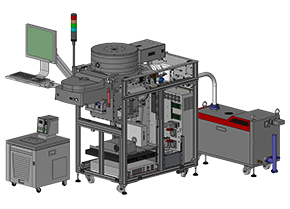

DRIE equipment

DRIE equipment must provide high ion current density to the substrate, efficient RF power coupling for substrate biasing, and efficient substrate cooling.

Manufacturers of etch equipment generally offer an etcher dedicated to deep etching of silicon in their product portfolio, but few also provide the capability to etch deep features into silicon carbide.

At CORIAL, we take a different approach, where we offer both system flexibility and low cost of ownership.

To exclusively support all DRIE applications (silicon, glass, silicon carbide etch), we have upgraded our ICP-RIE system, the Corial 210IL, to add a high-powered ICP reactor (usable range is 100 W to 2000 W), with wall temperature capability > 250°C. The system also features a novel cathode design with functionality down to -50°C, higher bias, and more efficient wafer cooling and power delivery.

The following options are also available to further enhance system performance:

- Retractable quartz liner to collect nonvolatile byproducts for excellent repeatability

- Dry vacuum pump and TMP pump with variable pumping speed for increased control over the chamber pressure

- Aluminum spacer to improve mask selectivity

DRIE processes

DRIE of hard-to-etch-materials such as sapphire, glass, and piezoelectrics, requires high ion current density.

DRIE of silicon requires a high radical concentration with a limited ion current to maintain good etch selectivity to the mask.

Precise control of process parameters is required to obtain the desired profile and feature dimensions. Process parameters such as pressure, RF power, ICP power, and wafer temperature are responsible for achieving desired sidewall angles (vertical or otherwise), with minimal trenching and surface roughness. Etch rate and mask selectivities are largely dependent on the process chemistry and RF power delivered to the plasma and the wafer.

Etch chemistry should be selected according to the materials to be etched. Namely, fluorinated chemistries are used to etch silicon-based compounds (Si, SiC, quartz), and chlorinated chemistries are well-suited for III-V semiconductors, sapphire, Ti DRIE, etc.

Products

Products

Corial 200 Series DRIE Etch System

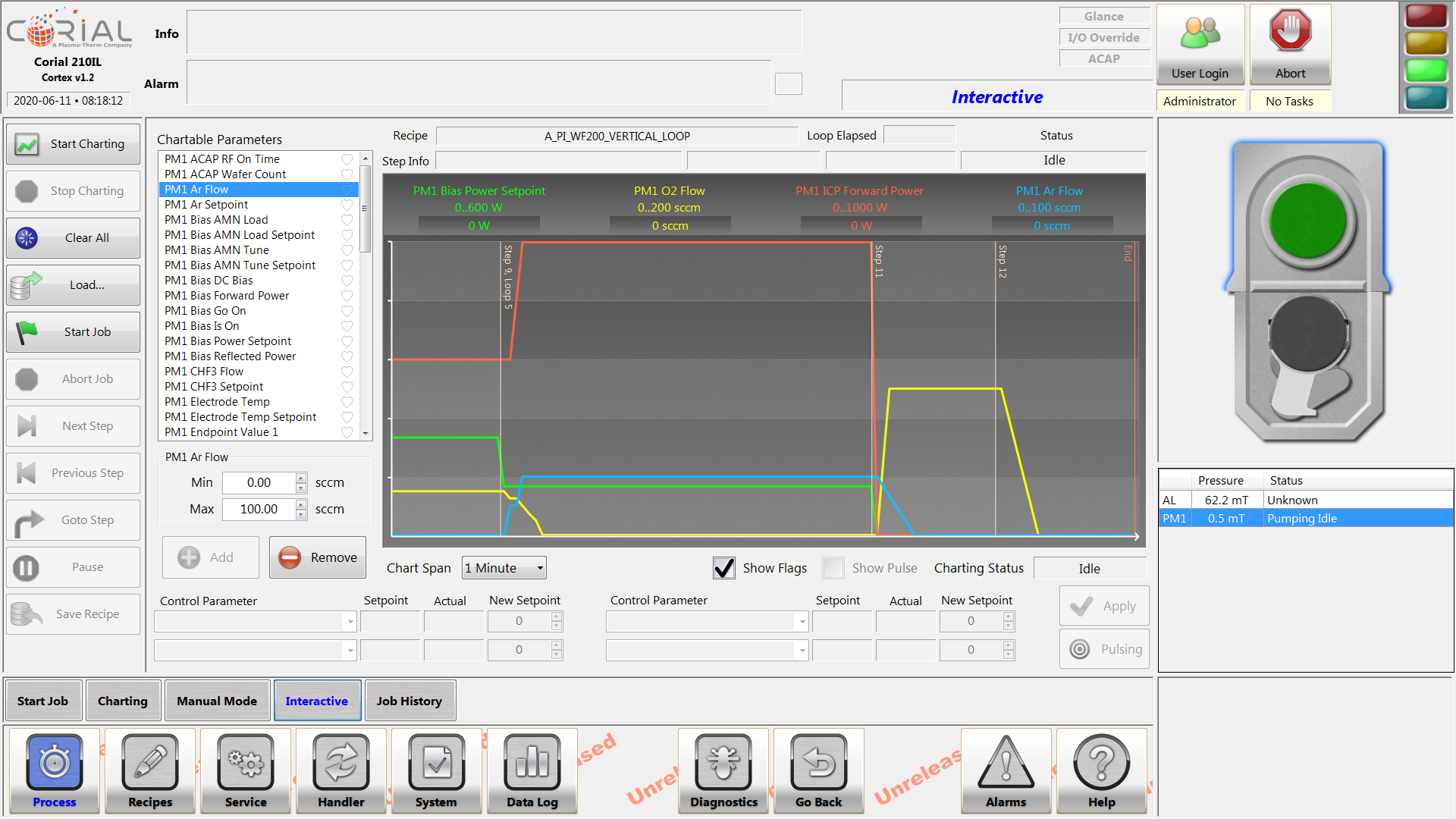

Process control software

Corial 210IL

- High-density plasma, high gas conductance, and fast process switching enable excellent profil control

- Heated chamber walls reduce polymer build-up to ensure excellent process repeatability

- In-situ plasma cleaning increases time between manual cleaning

CORTEX™ Pulse, control software for time-multiplexed processes

- Control and rapidly pulse any process parameter, with a minimum pulsing period of 10 milliseconds

- Enables DRIE (Bosch process) on conventional ICP-RIE systems

- Edit, store and use saved process recipes through unique graphical user interface