Forget about mechanical cleaning of your PECVD reactor and just deposit PECVD films with excellent uniformity and high deposition rates

Corial D250 PECVD system in brief

Corial D250 is designed for low volume production over a wide range of applications for the specialty semiconductor markets.

The Corial D250 PECVD system is based on CORIAL’s unique reactor design. It houses an isothermal, pressurized reactor within a vacuum vessel, which is different from conventional PECVD reactors with heated substrate holders. Featuring a next-generation gas showerhead and symmetrical pumping, the Corial D250 delivers excellent deposition uniformity for a wide variety of applications.

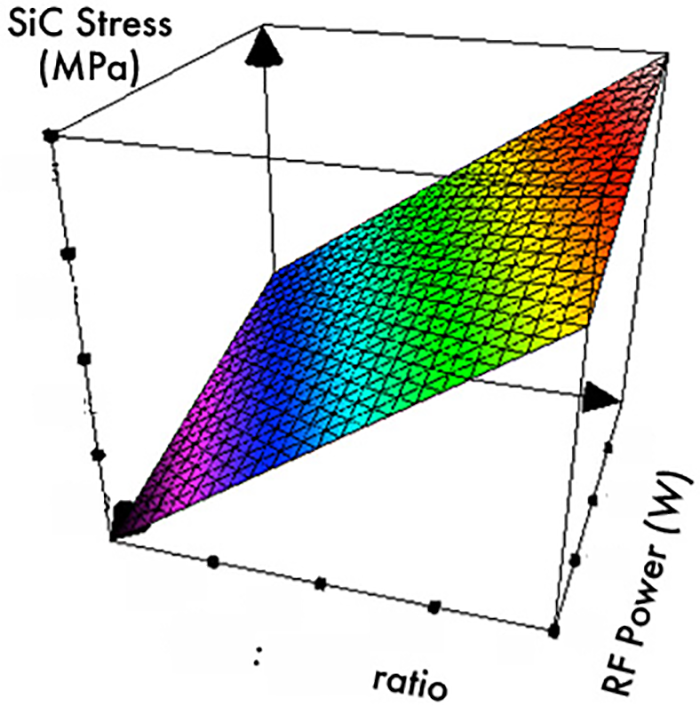

Optimizing film stress control is simple to accomplish thanks to the reactor’s symmetrical design.

COSMA Pulse software enables pulsing of any recipe parameter. The pulsing feature enlarges the process window to achieve better control of film properties, and supports Atomic Layer Deposition (ALD) in the Corial D250.

The Corial D250 PECVD system achieves rapid and uniform deposition for a wide range of materials including SiO2, Si3N4, SiOCH, SiOF, SiC and aSi-H films, on wafers up to 200 mm diameter.

This PECVD system can operate for years without the need for manual cleaning.

Key benefits

Key benefits

R

BEST REPRODUCIBILITY

Precise and uniform temperature control of the substrate and reactor walls delivers excellent deposition repeatability and uniformity

The pressurized, symmetrically-pumped reactor ensures high-quality films free of pinholes.

R

HIGH DEPOSITION RATES

With an isothermal and pressurized reactor, the Corial D250 delivers uniform, high deposition rates on wafer sizes up to 200 mm

Typical deposition rates: 520 nm/min for SiO2, 250 nm/min for Si3N4, 150 nm/min for SiOCH, 100 nm/min for SiC

R

PROCESS FLEXIBILITY

CORTEX™ Pulse software-controlled pulsing of any process parameters improves control of film properties and enables Atomic Layer Deposition (ALD) in the Corial D250 deposition system

R

INCREASED UPTIME

The Corial D250 high temperature, dual pumped configuration enables efficient plasma cleaning at operating temperature, with no corrosion of mechanical parts

No manual cleaning of reactor or vacuum vessel required for many years of operation

Related processes

Typical materials that can be processed with the Corial D250 PECVD system include:

- Silicon-based compounds : SiO2, Si3N4, SiOCH, SiOF, aSi-H

- Hard materials: SiC

The Corial D250 can serve a variety of applications in specialty semiconductors markets including:

- Optoelectronics

- MEMS

- Power devices

- Wireless Communication

- Integrated optics

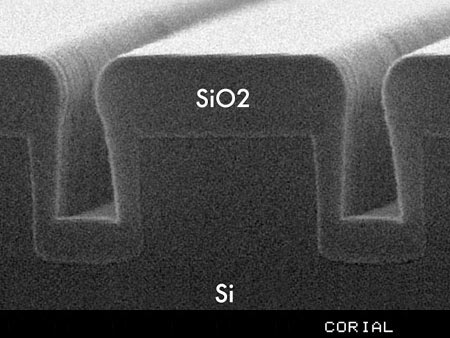

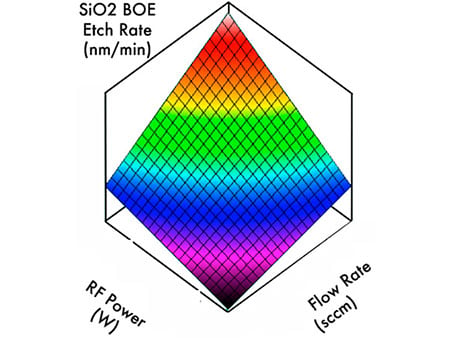

Silicon Dioxide (SiO2) PECVD deposition process for step coverage

MEMS

- Deposition rate 16 nm/min

- Refractive index 1.475

- Stress -250 ± 50 MPa

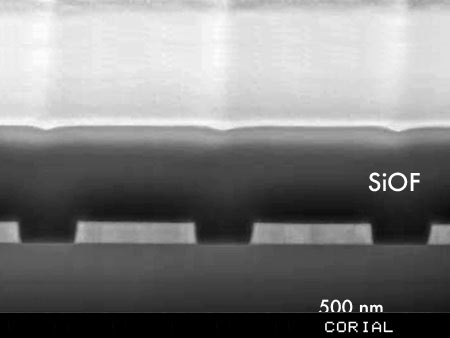

Fluorinated Silicon Oxide (SiOF) PECVD deposition process for step coverage

Wireless Communication

- Deposition rate 65 nm/min

- Refractive index 1.41

- Stress -30 ± 50 MPa

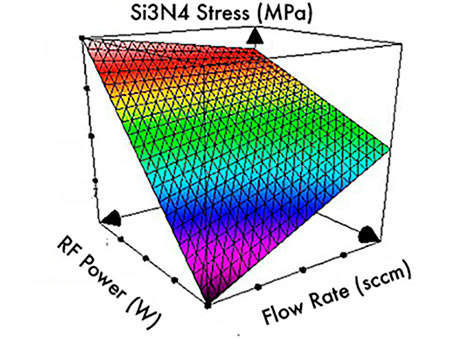

Stress-less Silicon Nitride (Si3N4) PECVD deposition process

MEMS

- Deposition rate 120 nm/min

- Stress -10 ± 50 MPa

- Deposition at 280°C

The Corial D250 PECVD system can be thoroughly customized with a wide range of features.

Additional gas inputs

Additional gas inputs (up to 8) for more complex process gas combinations

Variety of RF power supplies

Higher output power supplies with automatic matching network

Light tower

![]()

The signal light tower provides an easy-to-view indicator of the system’s processing status

Laser interferometry

End point detection by laser interferometry to enhance process control through automated measurement of etch/deposition rate, etch depth and deposition thickness