Cost-effective mask repair technology and MEMS devices manufacturing using the Corial 300S RIE system

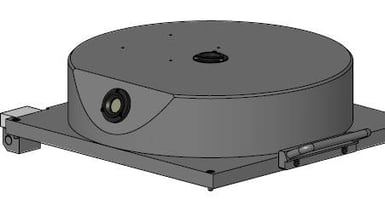

Corial 300S RIE system in brief

With chrome and quartz etch capabilities, the Corial 300S RIE system is ideal for mask repair. This product can process mask sizes from 2” x 2” up to 8” x 8”, thanks to a wide array of substrate holders.

The Corial 300S design includes a large cathode that facilitates substrate loading, and enables high chromium etch rates together with high selectivity to the PR. The substrate holders are simply clamped on the cathode without the need for screws or fasteners.

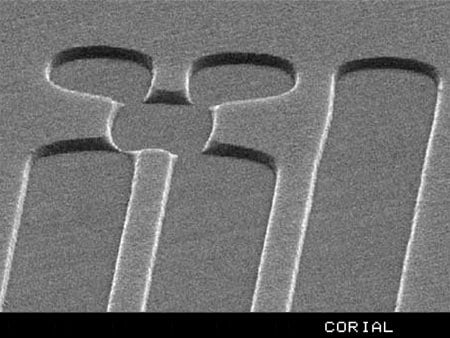

This simple-to-use, manually-loaded batch RIE system can etch a wide range of materials required for MEMS device manufacturing, including silicon, silicon compounds, metals, and polymers, using fluorinated gases. The tool accommodates batch sizes of 7 X 4” or 3 X 6” wafers.

The Corial 300S system can be upgraded with the next generation RIE process chamber, designed for etching and/or thin film sputtering, with any type of substrate up to 300 mm diameter.

Key benefits

Key benefits

R

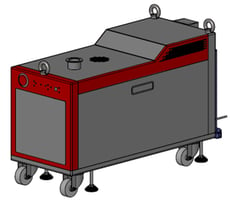

LOW COST OF OWNERSHIP

Cost-effective mask repair technology

Small (0.81 m2) footprint system with fast substrate loading and unloading

Retractable liner reduces cleaning requirements

R

BEST REPEATABILITY

Optimized helium backside cooling results in excellent process and wafer temperature control, and greater flexibility to process a wide range of materials

R

HIGH ETCH RATE CAPABILITY

Fast RIE rates: Cr (50 nm/min), SiO2 (50 nm/min), Si3N4 (60 nm/min) and polymers (400 nm/min)

Excellent etch control and etch rate determination with end-point detector

Related processes

Typical materials that can be processed with the Corial 300S RIE system include:

- Chrome and quartz for photomask repair

- Silicon and silicon-based compounds (SiO2, SiNx, Si)

- Polymers: Polyimide, BCB, Photoresist

- Metals: Au, Pt, Fe, Cu, PZT, Ti, TiN, TiW, W, Ta, TaN, Ge, Nb, NbN, Mo

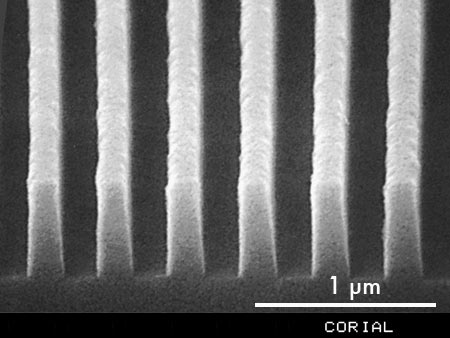

Chrome (Cr) etch with RIE plasma etch technology

Photomask

- Selectivity vs. quartz > 20:1

- Etch rate 50 nm/min

- Uniformity < ± 3%

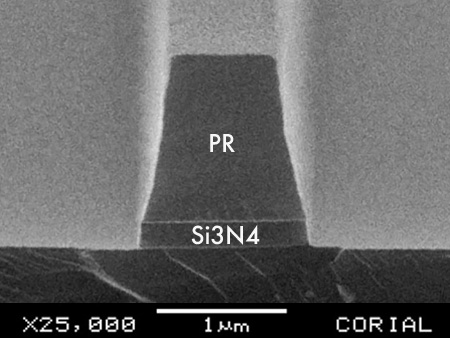

Silicon Dioxide (SiO2) RIE etch

MEMS

- Etch depth 800 nm

- Etch profile 88°

- Etch rate 50 nm/min

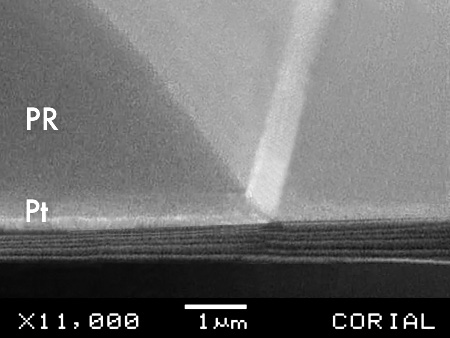

Metal back sputtering with RIE plasma etch technology

R&D

- Selectivity vs. PR mask > 1:1

- Etch depth 200 nm

- Etch rate > 50 nm/min

Upgrades

The Corial 300S RIE etch system can be thoroughly customized with a wide range of features.

Additional gas inputs

Additional gas inputs (up to 8) for more complex process gas combinations

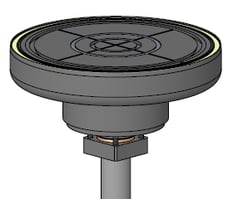

Chamber for sputter-etch

The RIE process chamber is designed for etching and/or sputtering of thin films on any kind of substrate, up to 300 mm diameter. The reactor is equipped with a retractable liner to collect etch by-products and/or sputtered materials, to increase time between cleans.

Wide temperature range cathode

Cathode supports low temperature capability down to -30°C

Variety of pumps

Dry Vacuum pump with varied pumping rate for increased control over the process chamber pressure

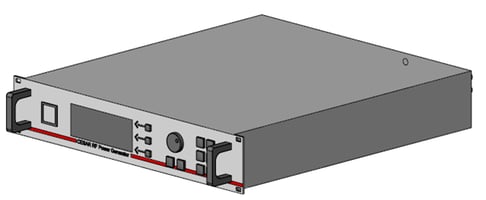

Variety of power supplies

Higher output power supplies with automatic matching network

Light tower

![]()

The signal light tower provides an easy-to-view indicator of the system’s processing status

Laser interferometry

End point detection by laser interferometry to enhance process control through automated measurement of etch/deposition rate, etch depth and deposition thickness