Compact, easy-to-use equipment for fluorine-based etching

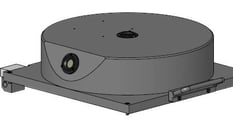

Corial 200S RIE etch system in brief

This simple-to-use, manually-loaded RIE system can etch a wide range of materials including silicon, silicon-based compounds, metals, and polymers with fluorinated gases.

The Corial 200S is ideal for R&D and can process substrates from small wafer pieces to full 200 mm wafers, thanks to a large variety of substrate holders.

The RIE reactor of the Corial 200S system can be equipped with a Ni coated liner, which extends time between cleans.

With helium back side cooling of the substrate, high sputter rates can be achieved (> 50 nm/min), while preserving the photoresist mask.

Key benefits

Key benefits

R

LOW COST OF OWNERSHIP

Small footprint (0.81 m2) system with rapid substrate loading and unloading

Low maintenance requirements

R

HIGH PERFORMANCE

Excellent process control enabled by efficient substrate cooling

Excellent etch control and etch rate determination with end-point detection

Related processes

Typical materials that can be processed with the Corial 200S RIE system include:

- Silicon and silicon-based compounds (SiO2, SiNx, Si)

- Polymers: Polyimide, BCB, Photoresist

- Metals: Au, Pt, Fe, Cu, PZT, Ti, TiN, TiW, W, Ta, TaN, Ge, Nb, NbN, Mo

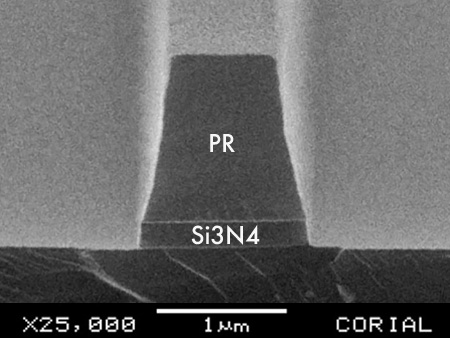

Silicon Nitride (Si3N4) etch with RIE plasma etch technology

R&D

- Etch depth 500 nm

- Etch rate > 70 nm/min

- Selectivity vs. Si underlayer > 7

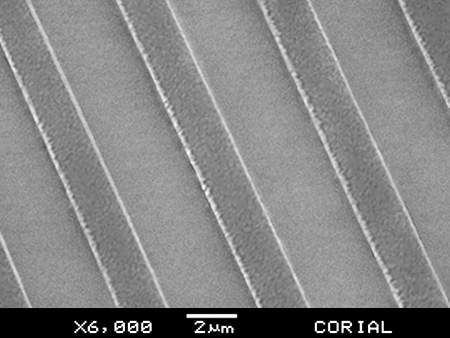

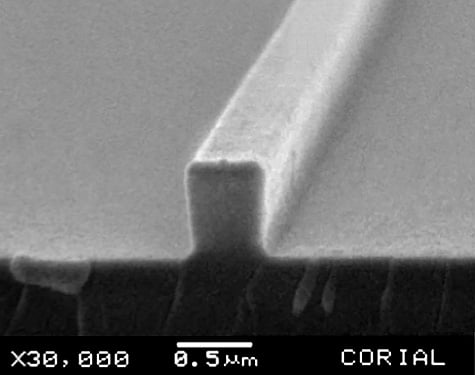

Tantalum (Ta) etch with RIE plasma etch technology

R&D

- Etch profile > 85°

- Etch rate > 90 nm/min

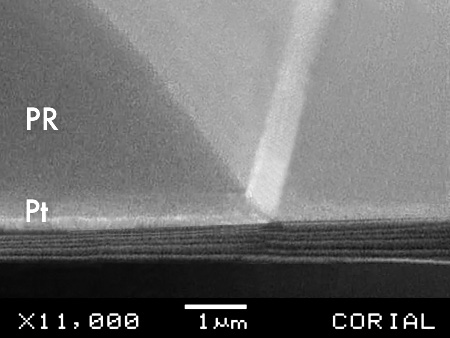

Metal back sputtering with RIE plasma etch technology

R&D

- Selectivity vs. PR mask > 1

- Etch depth 200 nm

- Etch rate > 50 nm/min

Upgrades

The Corial 200S RIE etch system can be thoroughly customized with a wide range of features.

Additional gas inputs

Additional gas inputs (up to 8) for more complex process gas combinations

Chamber for sputter-etch

The RIE process chamber is designed for etching and/or sputtering of thin films on any kind of substrate, up to 200 mm diameter. The reactor is equipped with a removable liner to collect etch by-products and/or sputtered materials, to increase time between cleans

Laser interferometry

End point detection by laser interferometry to enhance etch control through automated measurement of etch rate and etch depth

Light tower

![]()

The signal light tower provides an easy-to-view indicator of the system’s processing status