Simplicity, performance, and upgradability in a system designed for R&D environments

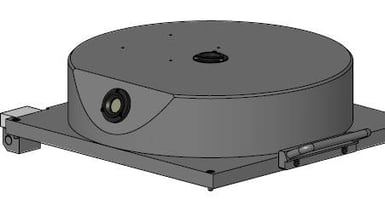

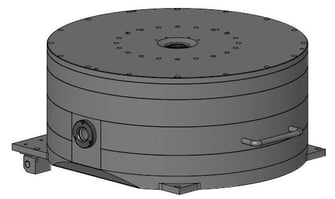

Corial 200R RIE etch system in brief

The Corial 200R is a compact, easy-to-use system for reactive ion etching of silicon-based compounds, metals and polymers.

With a direct-load design suitable for wafer pieces, or up to full 200 mm wafers, the Corial 200R is the ideal equipment for research and prototyping.

The Corial 200R etch tool is customizable, and can be upgraded after installation with an ICP source, load lock, additional gas lines …

Key benefits

Key benefits

R

COST EFFECTIVENESS

Small footprint, fully automatic operation, and low maintenance requirements

User-friendly process control software with intuitive GUI, recipe editor, and reprocessing capabilities

R

MODULARITY

The system can be upgraded from a simple RIE tool to an advanced ICP-RIE system with vacuum load-lock

The unique shuttle (carrier) design, combined with a standard cathode, enables a cost-effective reactor conversion, suitable for any application

R

HIGH PERFORMANCE

Optimized helium backside cooling of the wafer offers excellent process and wafer temperature control, and greater flexibility for processing a wide range of materials

Related processes

The Corial 200R system is designed for processing of materials that are compatible with fluorinated chemistries, including but not limited to silicon, silicon compounds, metals (Ge, W, Ta, TaN, Ti, TiN, TiW, Nb, NbN, Mo) and polymers.

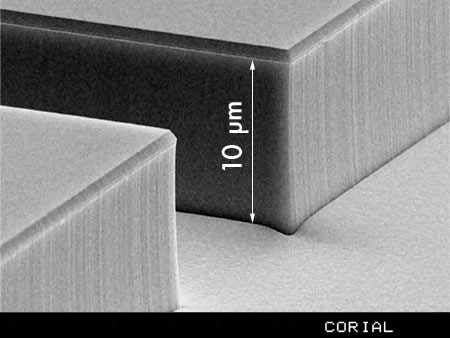

Fast InP etch with RIE plasma etch technology

R&D

- Selectivity vs. mask > 50:1

- Etch rate 80 nm/min

- Uniformity ±3%

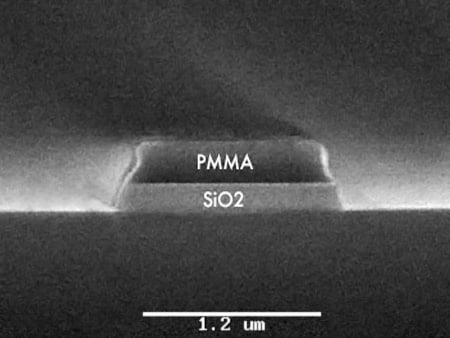

Polysilicon etch with RIE plasma etch technology

R&D

- Etch depth 500 nm

- Etch rate 120 nm/min

- Etch profile > 85°

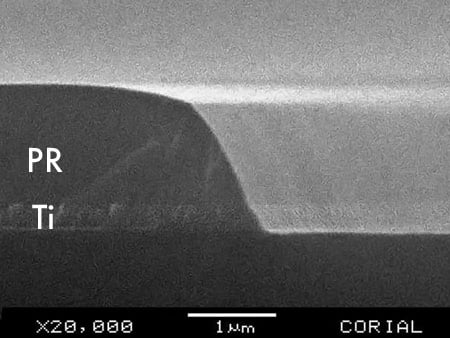

Low pressure Titanium (Ti) RIE etch

R&D

- Etch rate 25 nm/min

- Anisotropic etch profile

- Pressure ≤ 10 mT

Upgrades

The Corial 200R RIE etch system can be thoroughly customized with a wide range of features.

Additional gas inputs

Additional gas inputs (up to 8) for more complex process gas combinations

Chamber for sputter-etch

The RIE process chamber is designed for etching and/or sputtering of thin films on any kind of substrate, up to 200 mm diameter. The reactor is equipped with a removable liner to collect etch by-products and/or sputtered materials, to increase time between cleans

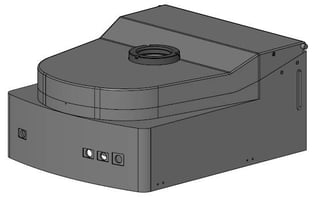

ICP reactor

The ICP reactor is designed for applications requiring a high-density plasma source. The ICP source results in improved etch rates, better uniformity, selectivity, and profile control

Load-lock

The addition of a load lock enhances process capability (allows the safe use of corrosive and toxic gases), and improves system performance (offers higher process repeatability and faster pump-down time)

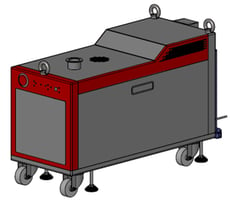

Variety of pumps

Dry Vacuum Pump with varied pumping rate for increased control over the process chamber pressure

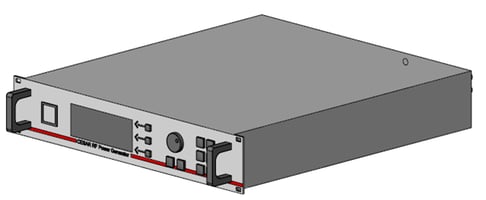

Variety of power supplies

Higher output power supplies with automatic matching network

Light tower

![]()

The signal light tower provides an easy-to-view indicator of the system’s processing status

Laser interferometry

End point detection by laser interferometry to enhance etch control through automated measurement of etch rate and etch depth