Industry-leading uniformity for etching silicon-based compounds and polymers

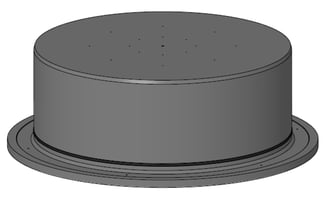

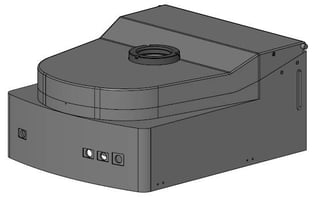

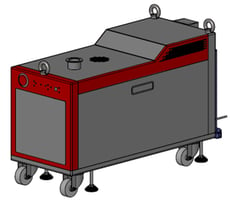

Corial 200I ICP etch system in brief

The Corial 200I ICP-RIE system is designed for R&D centers and IC failure analysis labs.

This equipment uses fluorine- and oxygen-based chemistries to provide leading edge etch rates and uniformities for full wafers of up to 200 mm, as well as dies or packaged dies.

Featuring a short pump-down cycle (<3 minutes), rapid reactor clean time (<20 minutes), and shuttle loading direct on the carrier, the Corial 200I guarantees high system uptime.

Key benefits

Key benefits

R

FLEXIBILITY

Processing of silicon-based compounds and polymers with multiple etching modes

The unique shuttle (carrier) design, combined with a standard cathode, enable a cost-effective reactor conversion suitable for multiple applications

R

HIGH PERFORMANCE

Exceptional uniformity, and repeatability enabled with a unique high-power ICP reactor with helical antenna

Wide pressure range offers capability to precisely tune the etch profile

R

SCALABILITY

Low-risk, cost-effective upgrades extend product capabilities and maximize return on investment

Related processes

Typical materials that can be processed with the Corial 200I ICP-RIE system include:

- Silicon and silicon-based compounds (SiO2, Si3N4)

- Polymers: PMMA, Polyimide, BCB, Photoresist

- Metals: Ti, TiN, TiW, W, Ta, TaN, Ge, Nb, Nbn, Mo

The Corial 200I offers differentiated technology and application-focused capabilities for the IC failure analysis and the R&D markets:

- Delayering of polymers and silicon-based compounds for sample preparation prior to IC failure analysis

- Capability to etch the wide range of materials used in R&D centers

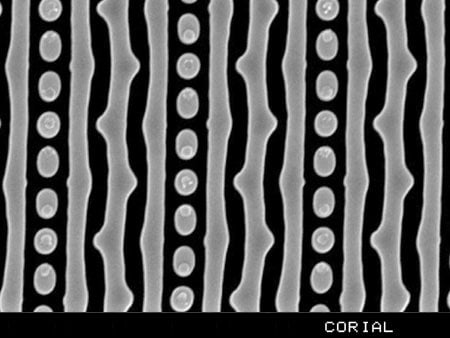

Deprocessing for 28 nm technology node

Failure analysis

- Low-K dielectric etching

- Etch rate 300 nm/min

- Selectivity vs. Al/Cu > 50:1

ILD deprocessing on wafer

Failure analysis

- SiO2 etching

- Etch rate 140 nm/min

- Selectivity vs. metal > 50:1

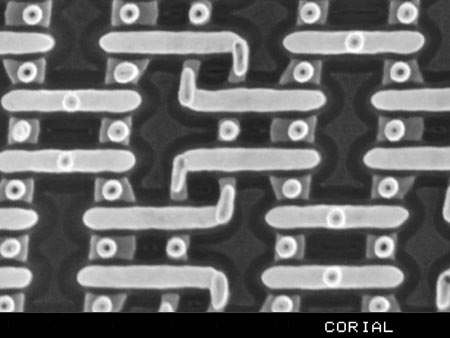

Silicon Dioxide (SiO2) RIE etch process

R&D

- Etch rate 45 nm/min

- Etch depth 800 nm

- Uniformity ±3%

Upgrades

The Corial 200I ICP-RIE etch system can be thoroughly customized with a wide range of features.

Additional gas inputs

Additional gas inputs (up to 8) for more complex process gas combinations

Liner for sputter-etch

Ni coated liner to collect sputtered materials in metal RIE sputter-etch mode

Quartz liner to collect sputtered materials in metal ICP sputter-etch mode

Load-lock

The addition of a load lock enhances process capability (allows the safe use of corrosive and toxic gases), and improves system performance (offers higher process repeatability and faster pump-down time)

Variety of pumps

Dry Vacuum Pump and TMP pump with varied pumping rate for increased control over the process chamber pressure

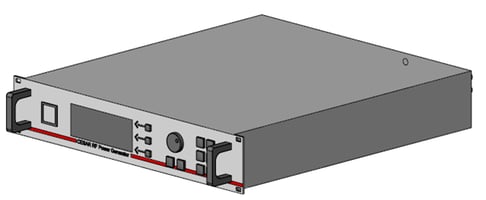

Variety of RF power supplies

Higher and lower output power supplies with automatic matching network

Light tower

![]()

The signal light tower provides an easy-to-view indicator of the system’s processing status

Laser interferometry

End point detection by laser interferometry to enhance etch control through automated measurement of etch rate and etch depth